- Home

- Products

- Software Device

- Fixed 3D View & Freeform View Features

- 3D View Shape designed Features

- User-selected assembly map Open/view/edit functionality

- Clip and Extents View capabilities via user tuning

- 3D drawings Markup function

- All Axes Triad Features by Part

- Point to Point measurement capabilities

- Measurement function by part

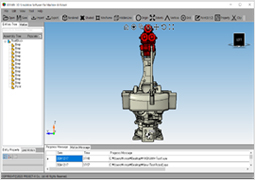

- Fixed 3D View & Freeform View Features

- 3D View Shape designed Features

- User-selected assembly map Open/view/edit functionality

- Clip and Extents View capabilities via user tuning

- 3D drawings Markup function

- All Axes Triad Features by Part

- Point to Point measurement capabilities

- Measurement function by part

- 3D drawing encryption (company-specific encryption)

(Solidworks, CATIA, Solidedge)

Unencrypted Step, IGES file view

Unencrypted Step, IGES file view

(e-Drawings)

(Customer Response)

(Electrical Design, Assembly)

(Design, Planning)

(Parts, Manufacture)

(e-Drawings)

(Solidworks, CATIA, Solidedge)

Creates encrypted 3D drawing file

Creates encrypted 3D drawing file

(viewX-ent)

Encryption-only 3D view program

Encryption-only 3D view program

(viewX-ent)

(Customer Response)

(Electrical Design, Assembly)

(Design, Planning)

(Parts, Manufacture)

(viewX-ent)

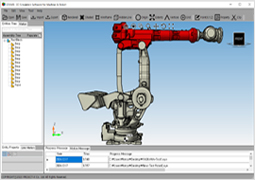

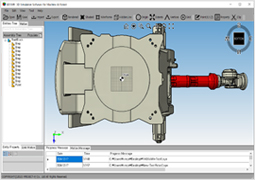

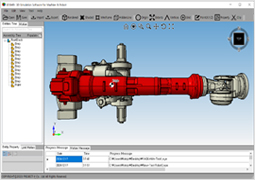

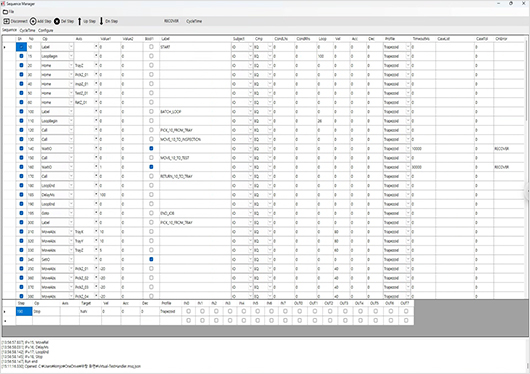

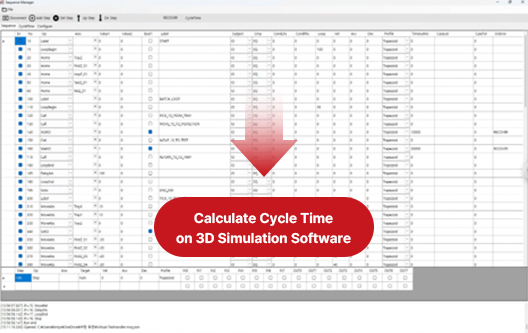

- Coding-free based logical sequence writing program

- A program that allows non-experts who have no control over equipment to design Logic

- Enabling optimization through integration with Large Language Models (LLM)

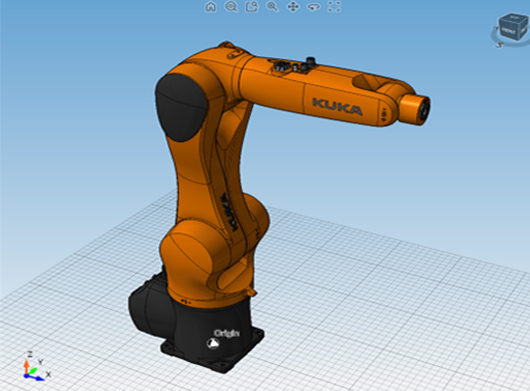

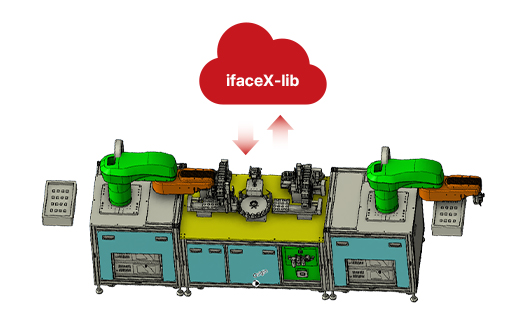

- Can handle 3D simulation in conjunction with roboX-designer

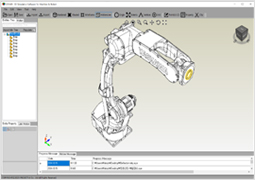

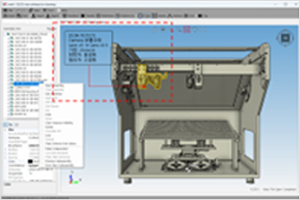

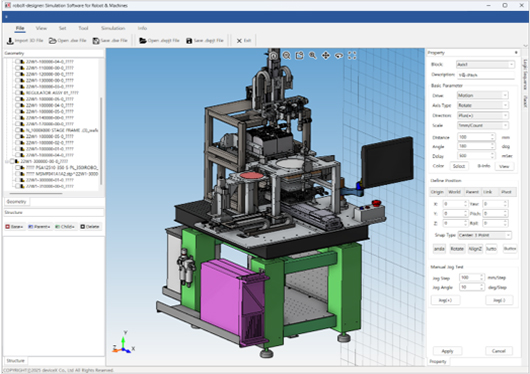

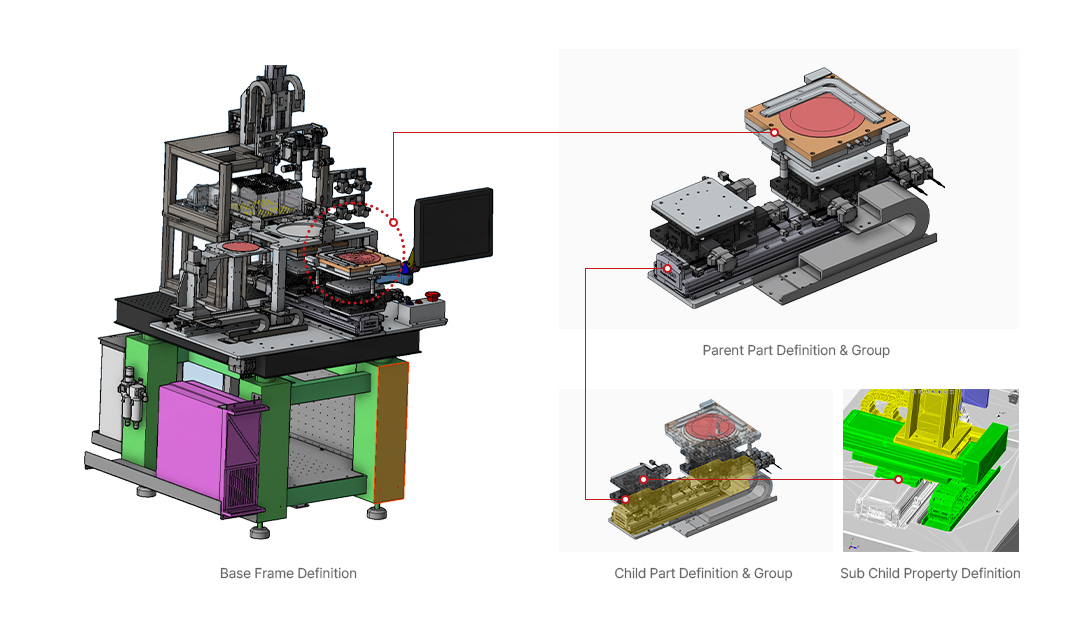

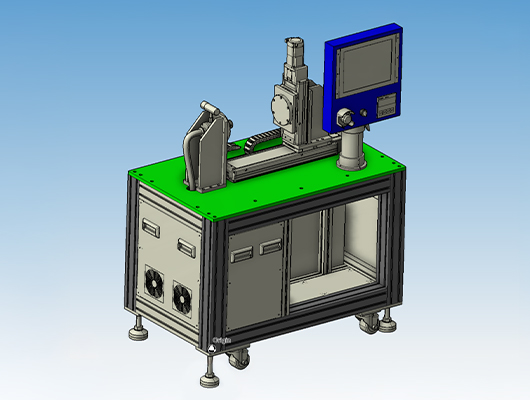

- Design program for simulation configurations based on .step files

- Sequence can be created in connection with roboX-logic that does not require coding

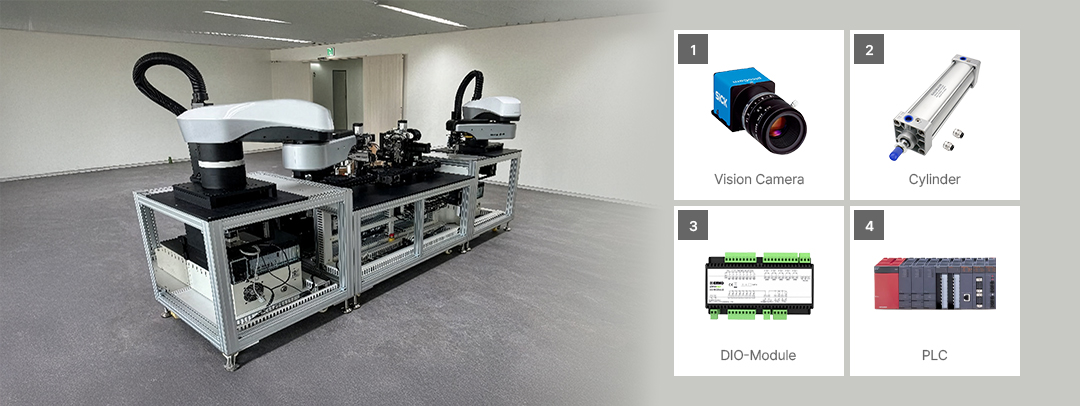

- It provides various motion controllers and device interfaces (ifaceX Library)

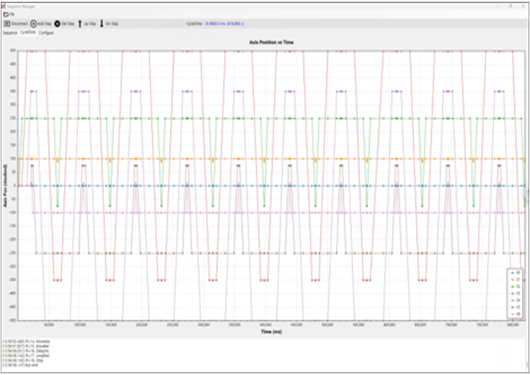

- Digital Twin operation, driving simulation, and cycle time analysis

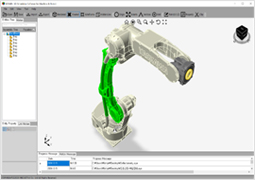

- Edit block grouping by moving device unit

- Defined and edited as Block Group-specific Properties for Motion driving

- Parameters: Distance, speed, acceleration, deceleration, interface, DIO setting

- Calculate the cycle time based on the sequence logic of the program

- 3D simulation collision detection

Expected Effects of 3D Simulation Software

- 01

It is possible to develop semiconductor equipment in a virtual environment without actual hardware

- 02

Efficiency of control logic verification and debugging

- 03

Validation of motion controller/PLC interworking

- 04

Optimization of semiconductor equipment automation process

Expected effect of 3D Simulation Software Localization

- 01

Ensuring technology independence and supply chain stability

- 02

Reduce deployment costs and optimize total cost of ownership (TCO)

- 03

Optimization of equipment linkage and ease of development tailored to domestic equipment companies

- 04

3D Simulation Software-based new industry application expansion and technology development are expected to increase employment

| Items | A traditional way of development | Apply 3D Simulation | Reduction effect |

|---|---|---|---|

| Development of control logic | 6 Month | 3 ~ 4 Month | Reduction of about 30% ~ 40% |

| Debugging and Verification | 3 Month | 1 ~ 1.5 Month | Reduction of about 50% |

| Equipment synchronization/integration test | 2 Month | 0.5 ~ 1 Month | Reduction of about 60% ~ 75% |

| Development and integration of full control SW | 11 Month | 3 ~ 7 Month | Reduction of about 35% ~ 45% |

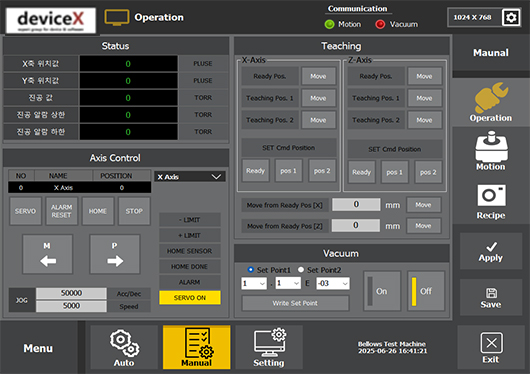

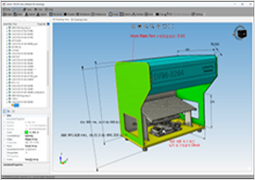

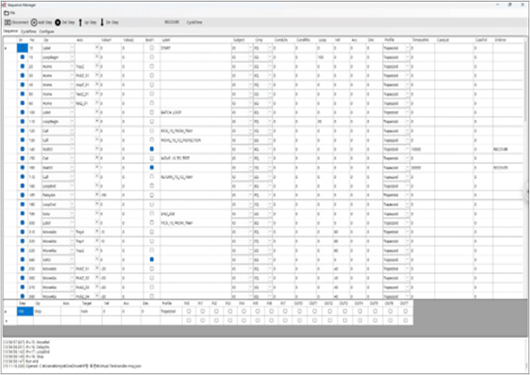

- Application software applied to precision measurement and testing equipment

- Develop user demand-based programs

- Provides a variety of measurement and analysis algorithms (including Chart and Log capabilities)

- Provides user convenience-based graphical user interface

- Provides various measurement and analysis functions such as current, voltage, pressure, vibration, stress, etc